Wax Injection Machine

What Is It?

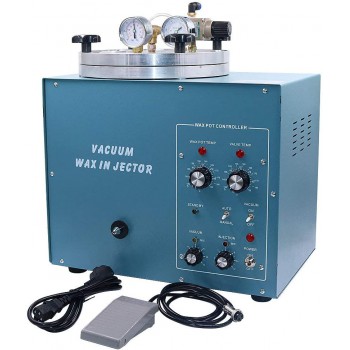

A wax injection unit is used in jewelry manufacturing to produce wax patterns that act as templates for metal casting. It forms detailed wax replicas by injecting heated wax into rubber or silicone molds, which are later used in investment or lost-wax casting processes. This equipment supports the preparation of models for rings, pendants, earrings, and similar components used in precious metal production.

Structure and Characteristics

A wax injector for jewelry includes a wax container, heating elements, pressure regulation components, and an injection nozzle. Some configurations provide digital interfaces that allow adjustment of temperature, pressure, and injection timing. The housing is generally constructed from metal or heat-resistant materials to handle thermal variation during operation. Capacity, pressure range, and control options vary depending on production scale, from compact workshop units to larger systems intended for continuous use.

What Should You Consider When Buying One?

When evaluating a wax injection machine , please review factors such as mold size, production volume, workspace limitations, and the type of wax commonly used. Compact or manual configurations can support low-volume or studio-based work. Systems with adjustable pressure and temperature controls may suit higher-output environments. Additional points to review include operating temperature range, pressure method, wax reservoir capacity, and nozzle compatibility with existing molds.

Purchase and Operation Considerations

Before purchasing, users should confirm voltage requirements, heating specifications, and air supply conditions. Wax characteristics such as melting point and viscosity should align with the equipment’s operating range. During use, filtering wax helps reduce nozzle blockage, and light preheating of molds can improve flow behavior. Maintaining balanced temperature conditions between wax and mold contribute to reduce surface defects in finished patterns. This type of equipment is applied in jewelry production facilities, casting workshops, and design studios for creating wax patterns used in metal forming.