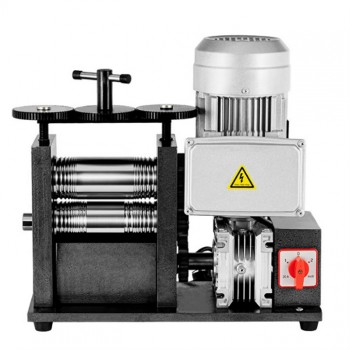

Jewelry Rolling Mill Machine

A jewelry rolling mill machine is a mechanical tool used to shape, flatten, and reduce the thickness of metal sheets and wires in jewelry production. It supports forming processes for materials such as gold, silver, copper, and brass. This type of equipment is commonly used in workshops, metal craft studios, and small-scale production facilities to prepare metal stock for further operations such as texturing, forming, or soldering.

What factors should to consider when choosing one?

When selecting this equipment, several technical factors should be reviewed:

Roller Type: Select flat, wire, or combination rollers based on production needs.

Roller Size: Larger rollers accommodate wider metal pieces, while smaller rollers are suitable for detailed work.

Operation Type: Manual versions fit low-volume use; motor-driven units support continuous operation.

Gear Ratio: Review the gear ratio to understand the effort required during rolling.

Material Compatibility: Confirm that the equipment supports the metals commonly processed in your workshop.

Application Range

This machine is used for flattening, thinning, and shaping metal sheets or wires in jewelry fabrication. It supports tasks such as forming ring bands, preparing metal plates for settings, producing wire for chains, and applying texture when decorative rollers are installed. It is adopted in both educational studios and professional jewelry workshops.

Buying Considerations

Before purchasing a jewelry rolling mill, review roller dimensions, gear structure, and handle design. Check availability of replacement rollers and spare parts. Consider workspace size and whether a manual or motorized version fits your setup. It is used to review assembly, lubrication, and maintenance guidelines provided by the manufacturer.