Ceramic Crucibles

What Is a Ceramic Crucible?

It is a container designed for heating and melting metals or other materials at elevated temperatures. It is typically manufactured from refractory substances such as alumina, silica, or porcelain, which tolerate repeated heating and cooling cycles. This type of container can be used in jewelry casting, laboratory work, and material testing, supporting clean containment of molten substances while limiting interaction between the vessel and the metal.

Main Features and Composition

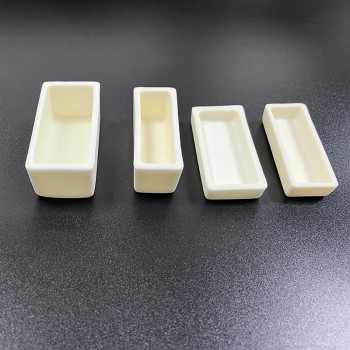

These vessels are available in multiple shapes, including cylindrical, conical, and square forms, to suit different furnace designs. Inner surfaces may be glazed or unglazed depending on the application. A glazed interior can help reduce chemical interaction with molten materials, while unglazed surfaces allow controlled thermal expansion and mechanical stability. Material composition influences resistance to temperature cycling and exposure to fluxes or metal alloys.

Purchase Considerations and Handling

Before purchase, users may review specifications such as maximum operating temperature, volume capacity, and compatible materials. Gradual preheating is recommended to reduce thermal shock during initial use. After melting, allowing the container to cool slowly helps maintain structural integrity.

Application Areas and Maintenance Tips

A ceramic crucible for melting gold is commonly used in jewelry workshops, research laboratories, and small-scale foundries. It can also be applied for processing silver, copper, or aluminum in educational or experimental settings. Routine inspection for cracks, surface wear, or residue buildup contribute to safe operation. Cleaning the interior after each melting cycle helps maintain material stability for subsequent use. Available options include various sizes and material grades to match different technical requirements and workspace conditions.