Graphite Crucibles

What is it?

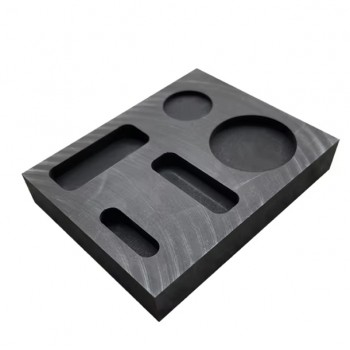

A clay graphite crucible is a container used for melting metals in jewelry casting, metalworking, and laboratory applications. It is manufactured from a blend of graphite and refractory clay, creating a dense structure capable of withstanding elevated temperatures. This type of container is commonly used to melt gold, silver, copper, and related alloys, while supporting even heat transfer during the melting process.

Working Principle

The working principle is based on the material's ability to absorb and distribute heat uniformly. When placed inside a furnace or casting system, it tolerates high thermal loads while holding molten metal safely. The graphite content assists heat conduction, while the clay component provides mechanical strength. During operation, the container gradually heats up and maintains the metal in liquid form before pouring. Smaller versions are often applied in benchtop or compact casting setups where metal volumes are limited.

How to Choose the Right One?

Selection depends on factors such as metal type, melting temperature, required capacity, and furnace compatibility. For jewelry production, small graphite crucibles are suitable for limited-volume gold or silver casting. Larger capacities may be chosen for batch processing in workshops. It can be used to compare dimensions, shape, and maximum operating temperature.

Application Areas

Before purchasing, users may review technical specifications such as capacity, material composition, and compatibility with specific furnaces or machines. Storage in dry conditions and gradual preheating before use help reduce thermal stress. These containers are commonly used in jewelry workshops, research laboratories, training environments, and small-scale metal foundries. Available models include compact sizes for manual use as well as standard formats for automated casting systems.