Jewelry Spot Welder

What is it?

A jewelry spot welder is a device designed to join small metal components by generating heat through electrical resistance. It is commonly used in jewelry repair, manufacturing, and fine metalwork involving delicate parts. This equipment applies a controlled electrical discharge to fuse metals without the use of additional solder, supporting detailed connection work in chains, rings, prongs, and metal frames.

Construction and Key Features

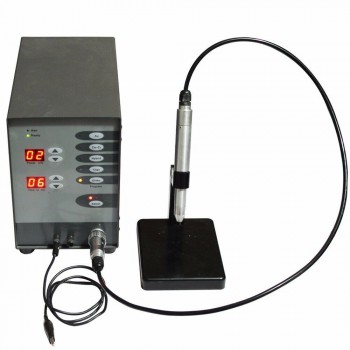

A typical system consists of a power supply, electrode arms, and a control interface. Copper or tungsten electrodes deliver current directly to the workpiece. The control unit allows adjustment of parameters such as current level, pulse duration, and pressure based on material type and thickness. Available models range from compact benchtop units to larger workshop configurations. Many designs include digital displays to support repeatable parameter settings for routine tasks.

What should you consider when buying one?

When selecting a suitable unit, users may evaluate factors such as metal type, joint thickness, available power output, and workspace constraints. Compact designs are often used for repair or custom work. For higher-volume or continuous operations, equipment with adjustable energy settings and multiple pulse options may better support varied applications. It is also used to review electrode compatibility and availability of replacement components before purchase.

Application Areas

These jewelry spot welding machines are used in goldsmithing, silverware production, watch repair, and small-scale metal fabrication. They support joining components such as chains, jump rings, settings, and frames. In addition to jewelry-related work, they may also be used in laboratory environments for controlled metal joining tasks where localized heat application is required.